Glass Bottle Manufacturing Process – Ruisheng Glass

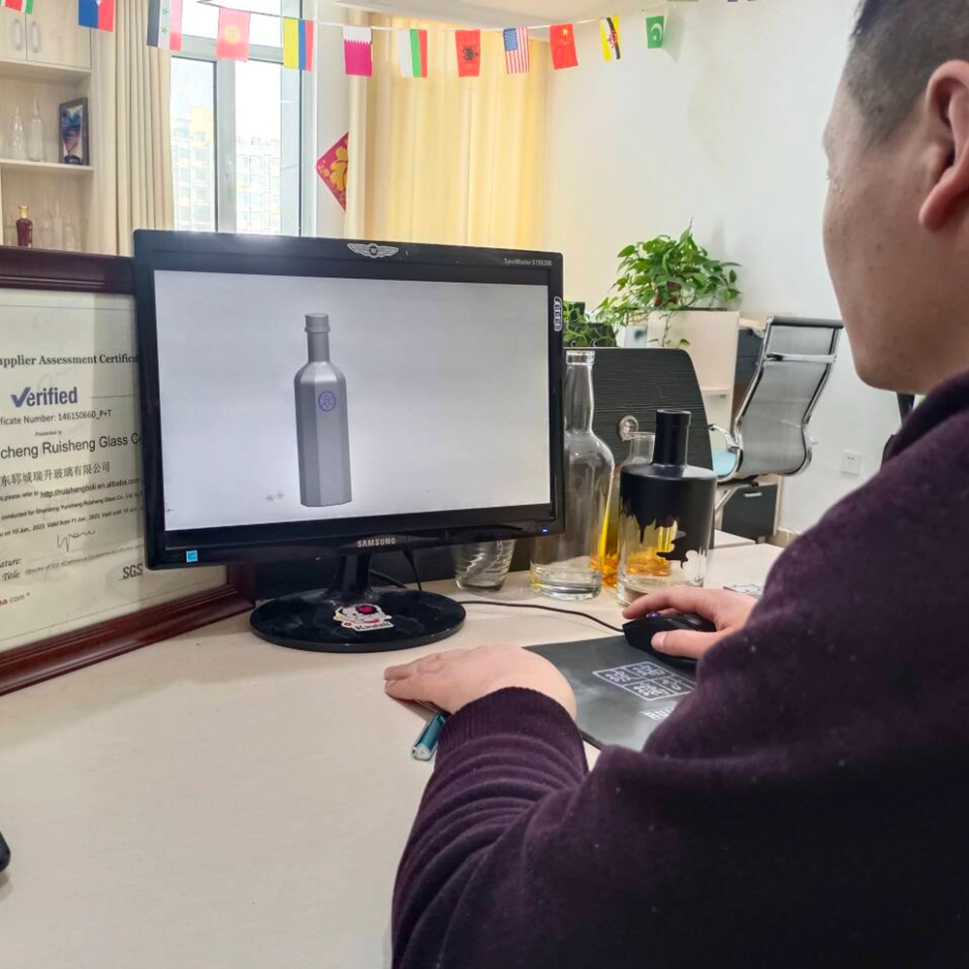

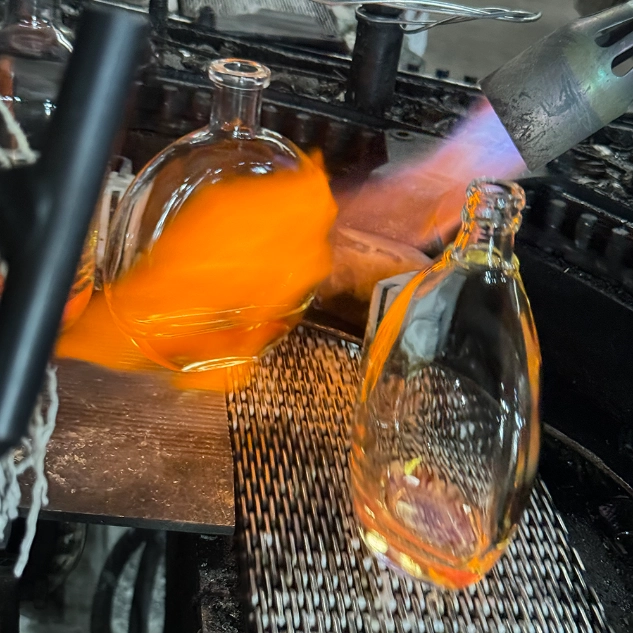

Ruisheng Glass is one of the leading liquor bottle manufacturers in northern China. We focus on the core product lines of super flint and high flint glass bottles, offering both standardized production and personalized customization services. Currently, we have over 10,000 existing bottle designs. Moreover, we can customize different capacity specifications according to customers’ ideas, combined with deep – processing techniques such as frosting, spraying, silk-screening, electroplating, and hot stamping. This can meet the packaging needs of various industries, including liquor, beverages, and perfumes, providing customers with a “one – stop” production service from mold manufacturing to post – decoration. From raw material selection to final inspection, our strict quality control ensures that every product meets safety and durability standards.