Customized Solutions For Your Business

Our R&D team has 70+ members, covering diverse fields such as material science and engineering. Each member has in-depth knowledge of product development. Collaboration and communication are emphasized for a smooth project process. We’re dedicated to providing excellent products and services to meet customer needs. A specialized, collaborative, efficient team offers better products and services.

Our R & D Capabilities

As a glass bottle manufacturer, our product design philosophy is always to keep pace with the times. We gain a deep understanding of the changing needs of our clients.

Constantly seeking innovative solutions to meet customer needs is our goal. Our designers have rich experience and professional knowledge.

They can design products that are beautiful in appearance, high in quality, and versatile in function.

We always pay attention to the practicability and environmental protection of our products. And fully consider recyclable materials in the design.

We can provide customers with the best products through continuous efforts and innovation. At the same time, we contribute to protecting the environment.

Planning

In the planning stage, we will deeply understand customers’ needs and market trends and formulate research and development plans and goals.

Design

The design team will propose innovative design solutions according to customer needs and market trends. We will conduct initial evaluation and optimization.

Development

We transform designs into actual products and test and evaluate them. We make 3D printing samples according to drawings. Finally, make molds and glass bottle samples according to the drawings.

Test

We do six tests per batch of bottles. Mainly test the bottle’s heat resistance, pressure resistance, transparency, etc. Before the order is delivered, the inspector will conduct a sampling test to ensure that each bottle meets our standards.

Technical Ability To Make Glass Bottles

| Test Equipment List | |||

| Equipment Name | Model | Brand | Test items |

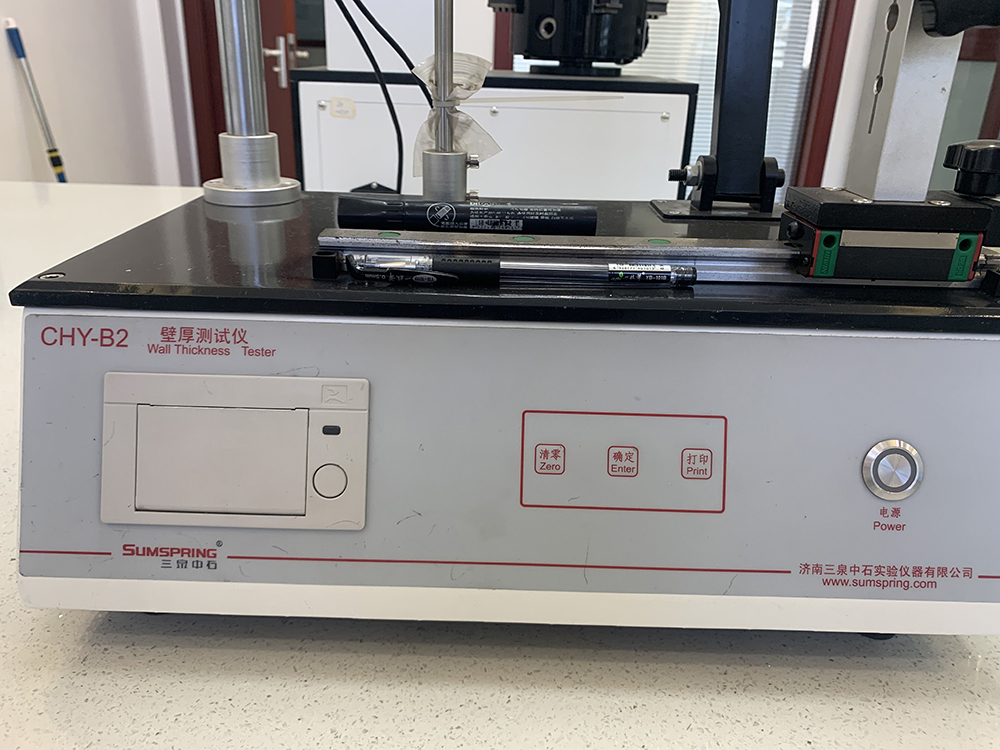

| Wall Thickness Tester | CHY-B2 | SumSpring | Wall Thickness Bottom Thickness |

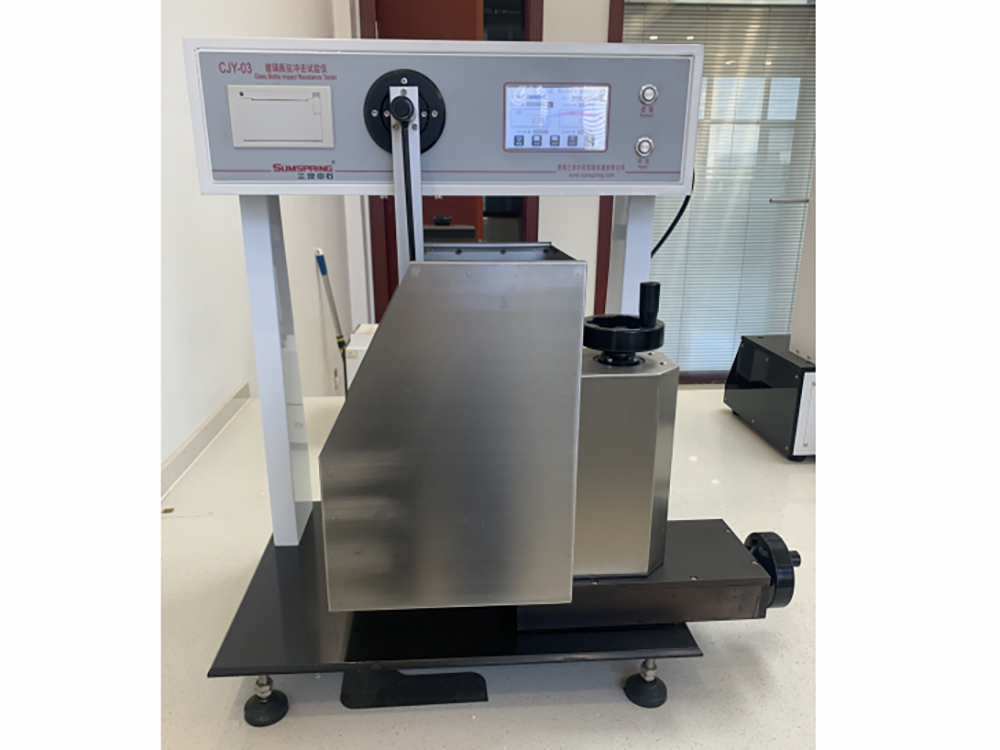

| Glass Bottle Impact Resistance Tester | CJY-03 | SumSpring | Impact Resistance |

| Glass Bottle Pressure-Resistance Tester | NLY-03 | SumSpring | Internal Pressure |

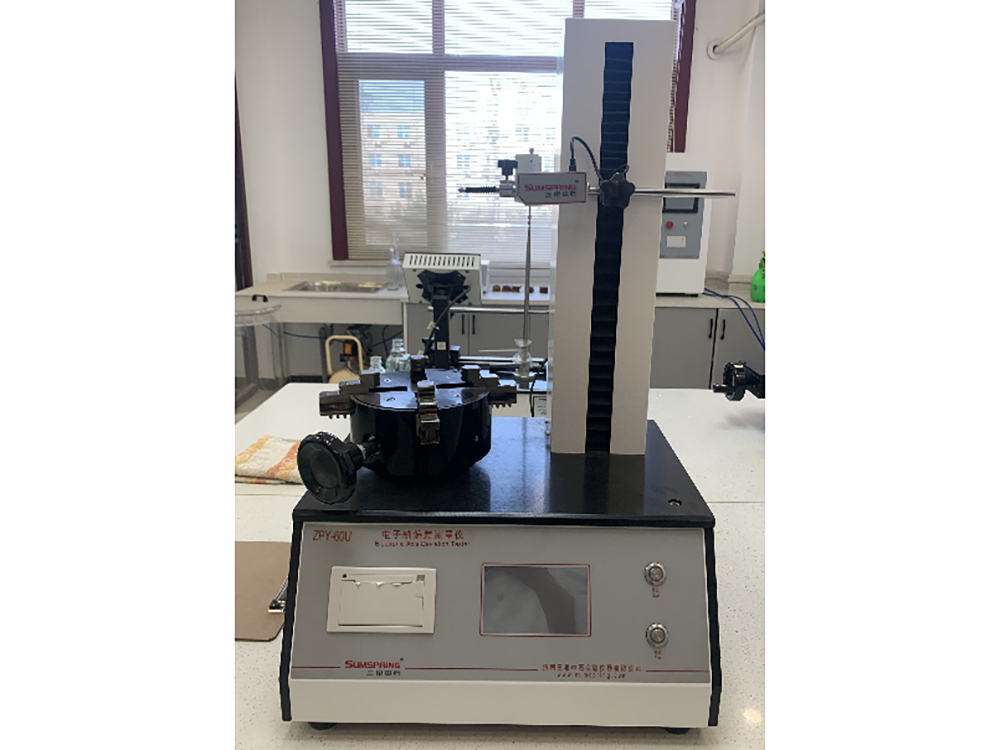

| Electronic Axis Deviation | ZPY-60U | SumSpring | Perpendi Cularity |

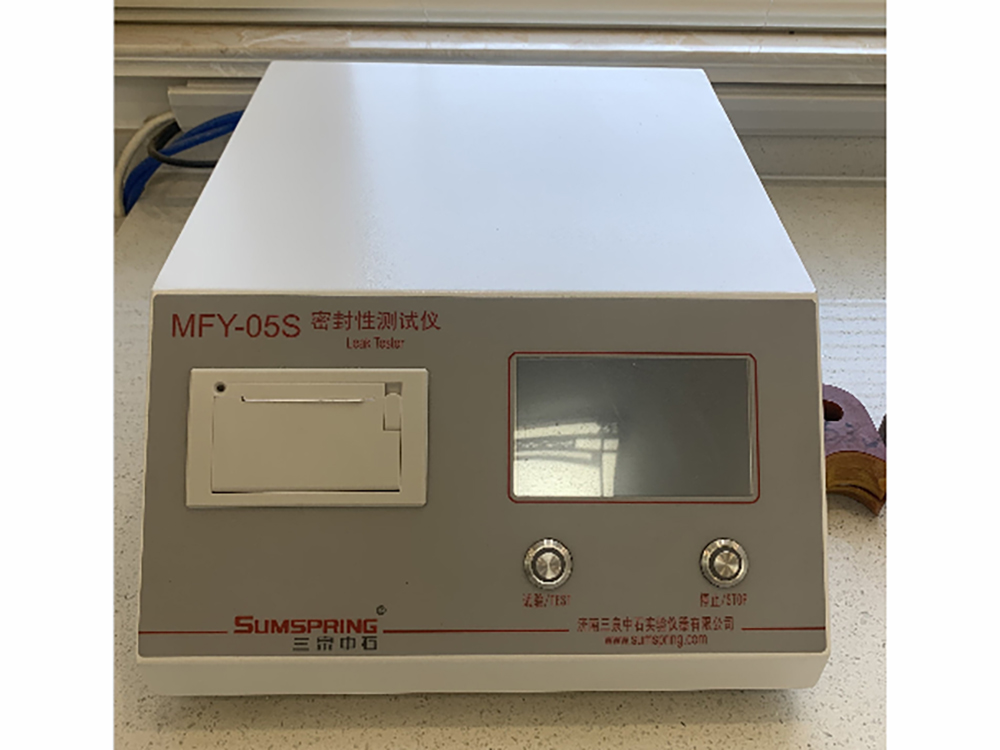

| Leak Tester | MFY-05S | SumSpring | Leakage Test |

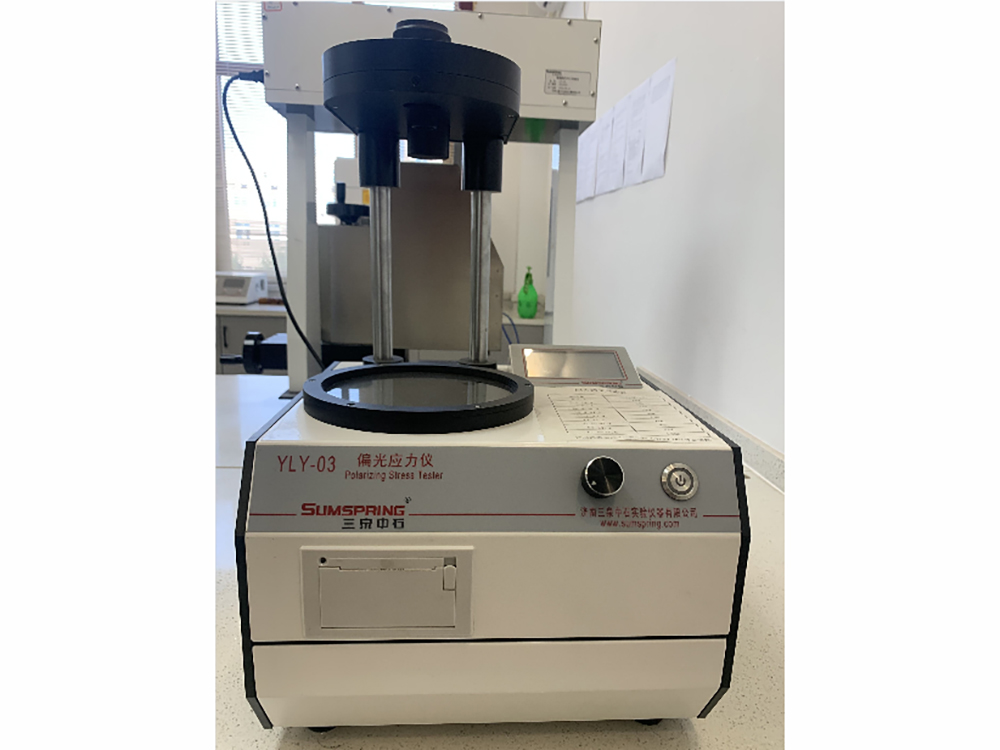

| Polarizing Stress Tester | YLY-03 | SumSpring | Inernal Stress Annealing Stress |

Wall Thickness Tester

Glass Bottle Impact Resistance Tester

Glass Bottle Pressure-Resistance Tester

Electronic Axis Deviation

Leak Tester