Custom Glass Bottle Design – Ruisheng Glass

Ruisheng has been deeply engaged in the glass packaging industry for 17 years. With mature production technologies and innovative design capabilities, we offer flexible, diverse customization solutions for global customers. We not only have over 10,000 ready-to-use bottle shapes for direct selection but also a professional in-house design team that can accurately bring your creative ideas to life. From standard selection to exclusive customization, the whole process is efficiently connected, making your brand packaging stand out.

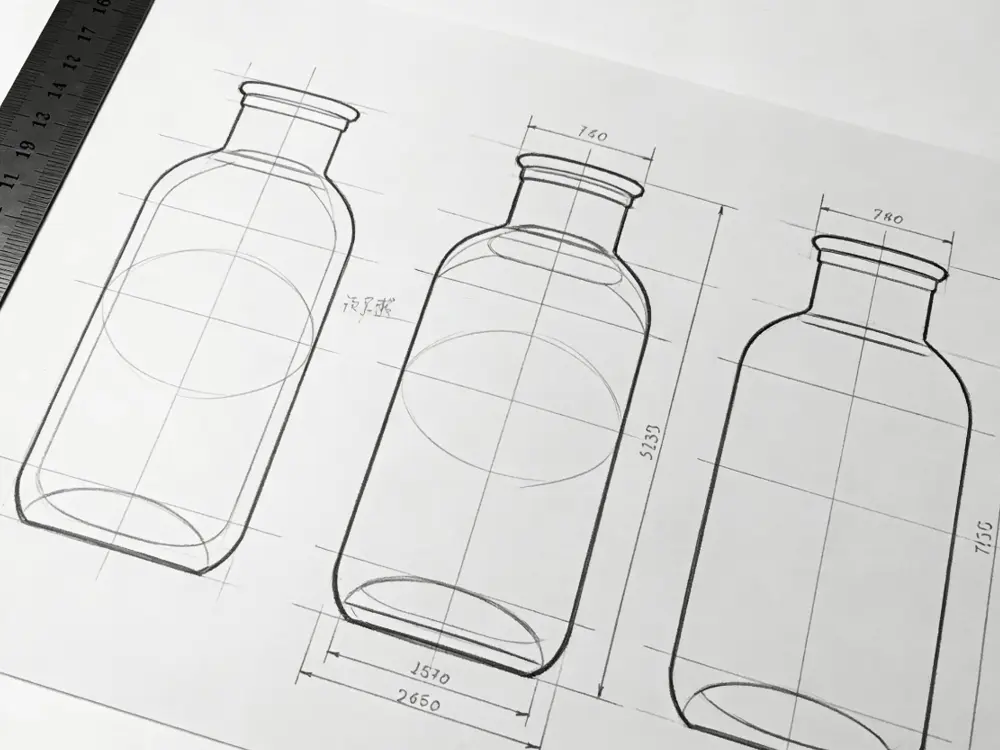

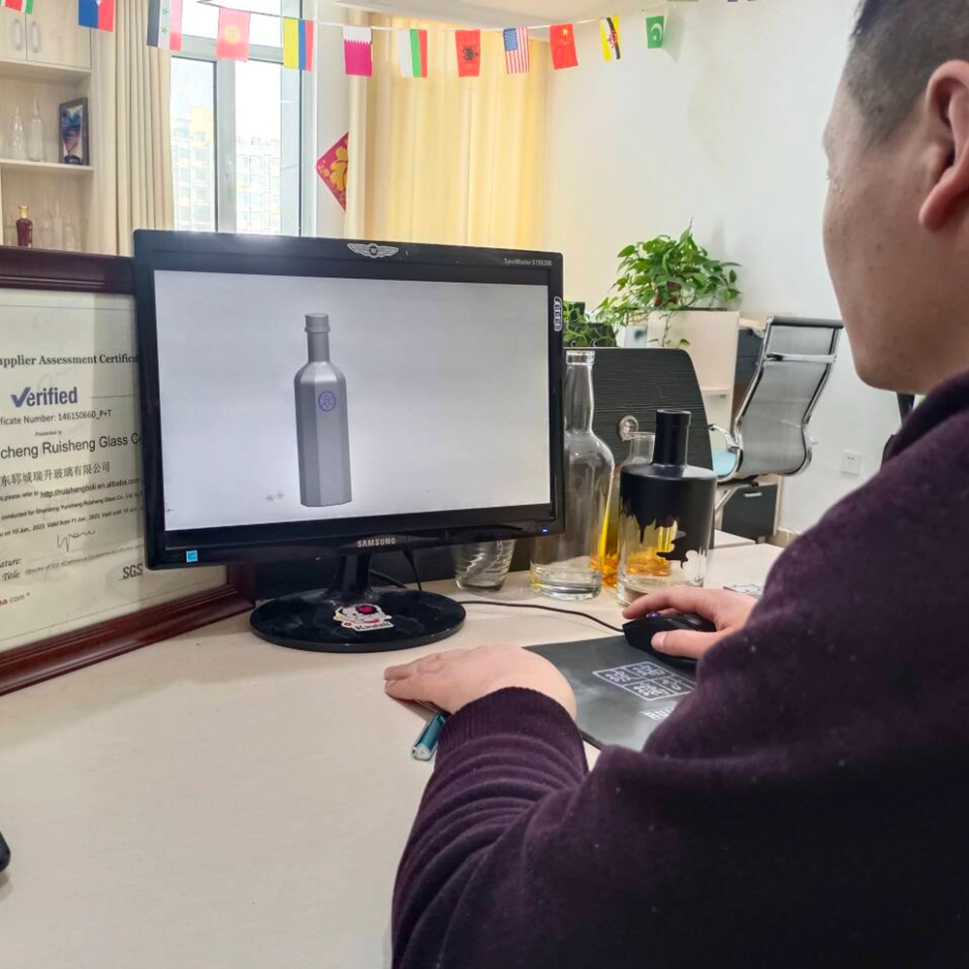

Custom Glass Bottle